At CGS, we develop precision-engineered solutions tailored to each customer’s unique needs. By blending today’s technology with our decades of industry expertise, we consistently deliver performance that goes beyond expectations!

Industry Leaders in Centerless

Grinding Solutions, Since 1990

Your Single Source Partner

Grinder Parts

Minimize downtime. Cost-effective and direct replacement parts for Cincinnati, Landis RK and Landis Viking parts to extend your centerless grinding machine lifespan.

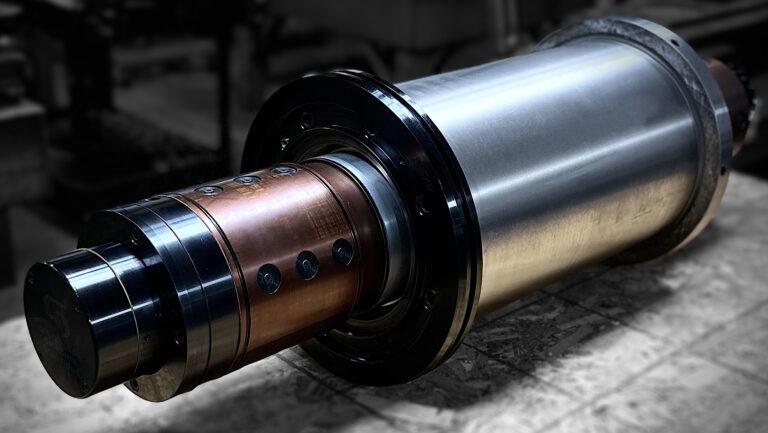

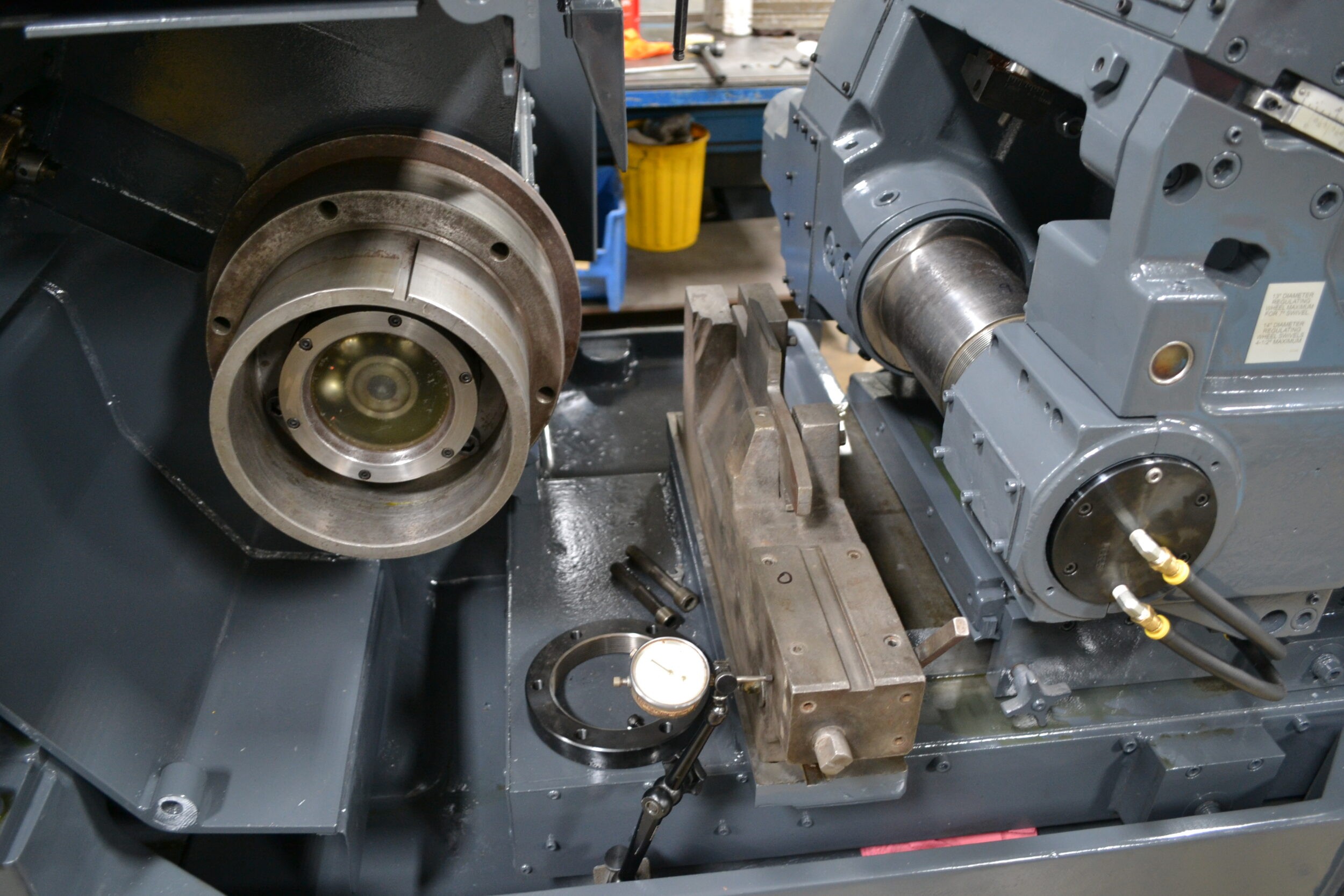

Grinder Components

Keep your equipment in optimal condition. Grinding Wheel Spindles, Regulating Slide Stack Assemblies, Landis Viking Spindles and more.

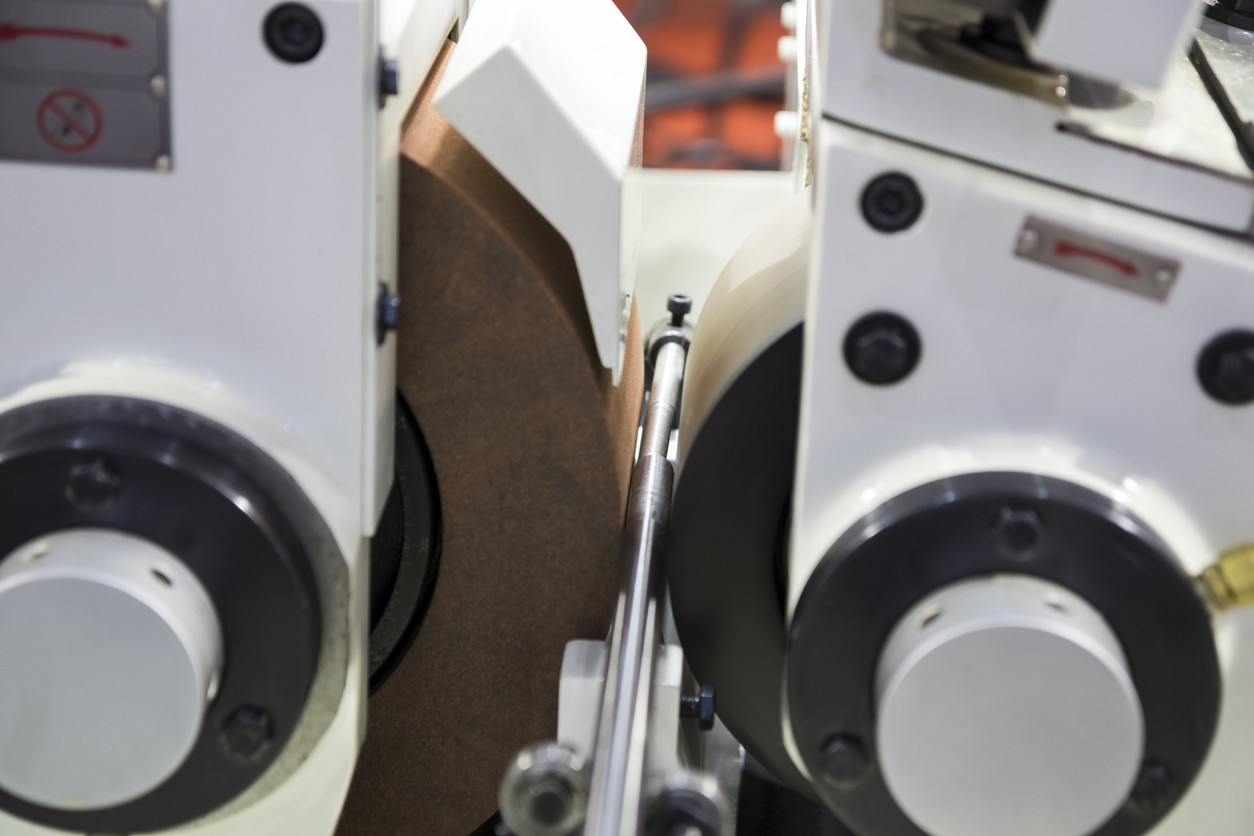

Tooling

The right tooling can make all the difference. Maximize precision with high-quality Workrest Blades, Bar Fixture System, and Grinding Wheels & Regulating Wheel.

Preventative Maintenance

Ensure machine reliability and longevity with our proactive maintenance services, minimizing downtime and optimizing performance.

Service & Repair

When unexpected issues arise, our expert technicians are ready for fast, reliable, on-site support, keeping your grinding operations running smoothly.

Training

Equip your team with the technical expertise to maximize the potential of our upgraded and retrofitted machines, and keep the legacy alive.

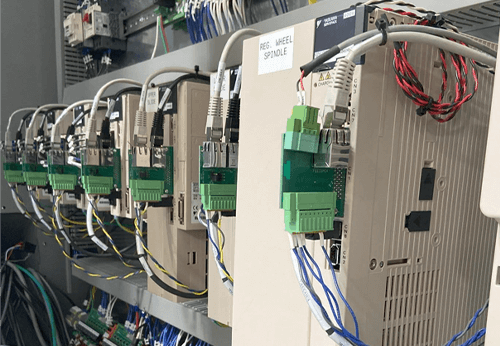

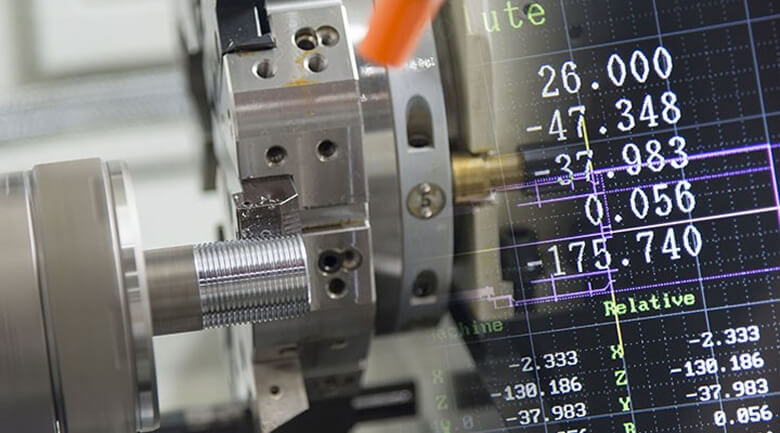

Integrate Advanced Machine Upgrades & Retrofits

Achieve superior accuracy, speed, and quality in your grinding processes with advanced CNC Controls, Regulating Wheel Servo Conversion and other Centerless Grinder Upgrades.

Which Centerless Grinder is Right For You?

#2OM Centerless Grinder

#2OM Centerless Grinder

- 20″ Grind Wheel Diameter

- 8” Wide Grinding Wheel & Regulating Wheel

- 15 HP Grinding Wheel Horsepower

- Cantilever Spindles

- 6,500 SFPM Grinding Wheel

- Cast Iron Base & Components

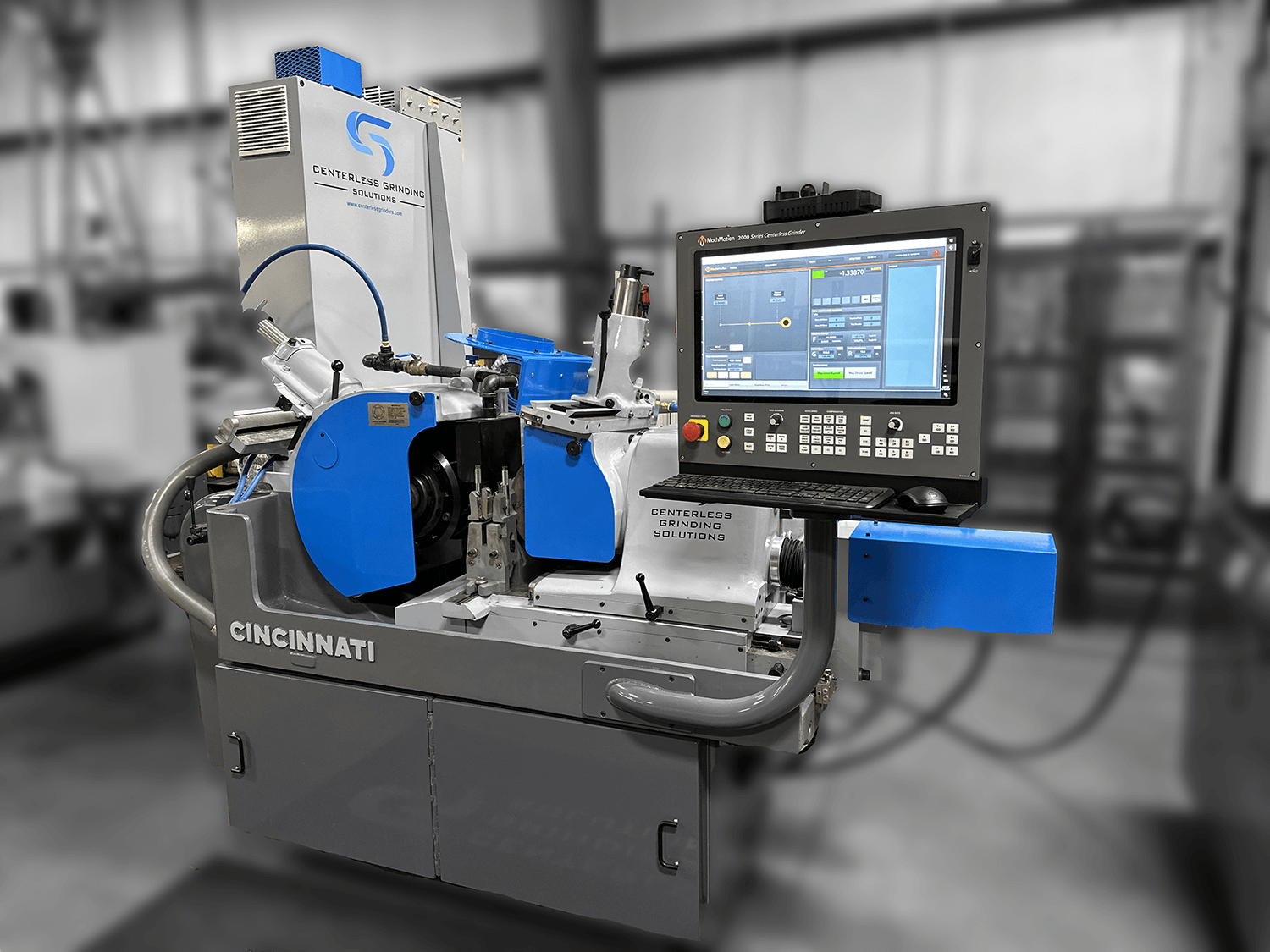

220-8 Cantilever Centerless Grinder

220-8 Cantilever Centerless Grinder

- 24” Grinding Wheel Diameter

- 8” Wide Grinding Wheel & Regulating Wheel

- 20 Hp Standard Grinding Wheel Motor*

- Cantilever Grinding Wheel Spindle; Outboard Support Regulating Wheel Spindle

- 6500 SFPM Grinding Wheel

- Cast Iron Base & Components

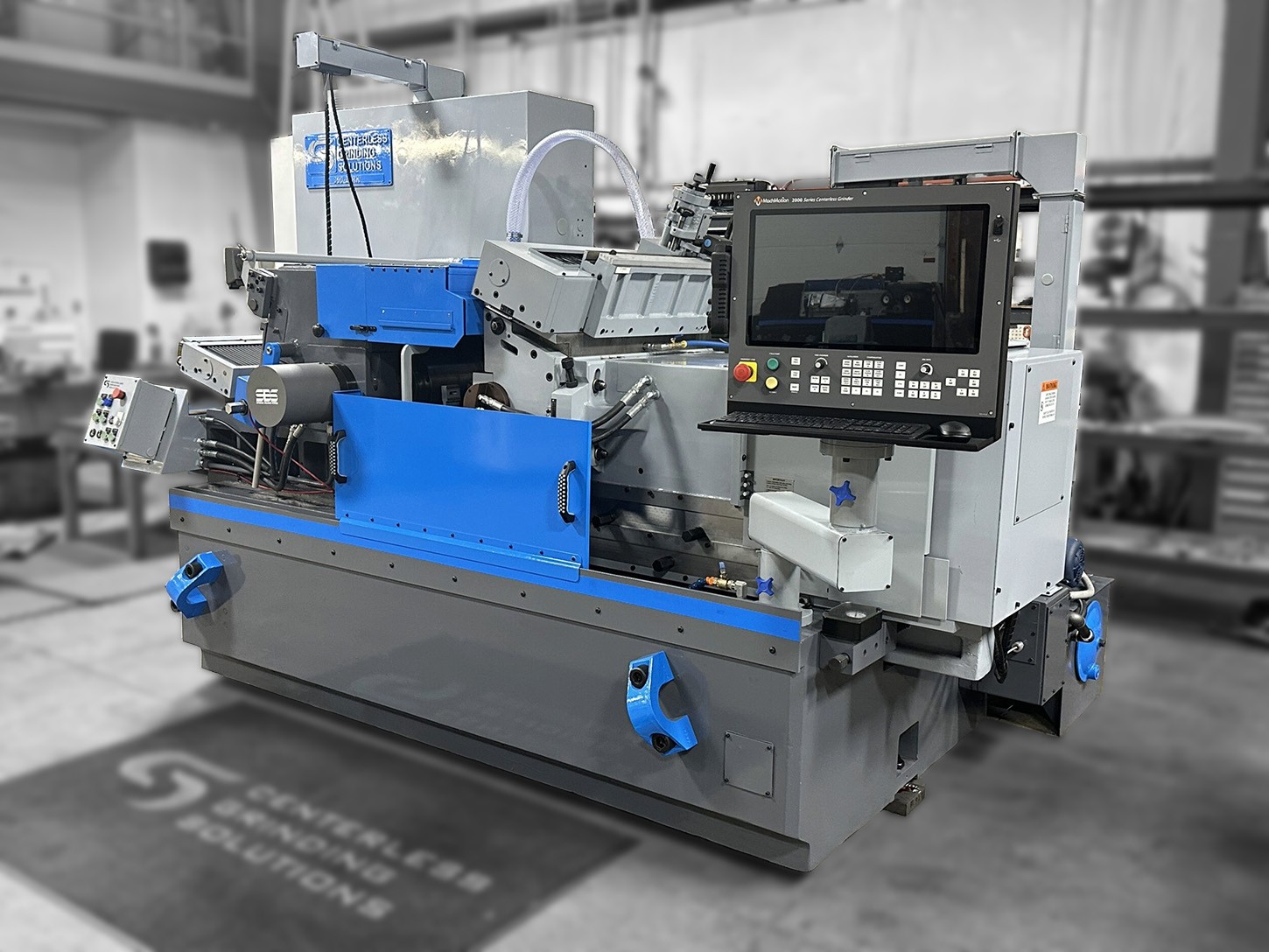

230-10 Twin Grip Centerless Grinder

230-10 Twin Grip Centerless Grinder

- 24″ Diameter Grinding Wheel

- 10″ Wide Grinding Wheel & Regulating Wheel

- 30 HP Grinding Wheel Motor

- “Twin Grip” Support-Grinding Wheel & Regulating Wheel Spindle

- 6,500 SFPM Grinding Wheel

- Cast Iron Base & Component Construction

340-20 Twin Grip Centerless Grinder

340-20 Twin Grip Centerless Grinder

- 24″ Grinding Wheel Dia

- 20″ Wide Grinding Wheel & Regulating Wheel Width

- 40 HP Grinding Wheel Motor

- “Twin Grip” Supported Grinding Wheel & Regulating Wheel Spindles

- 6,500 SFPM Grinding Wheel Speed

- Heavy-Duty Design & Construction

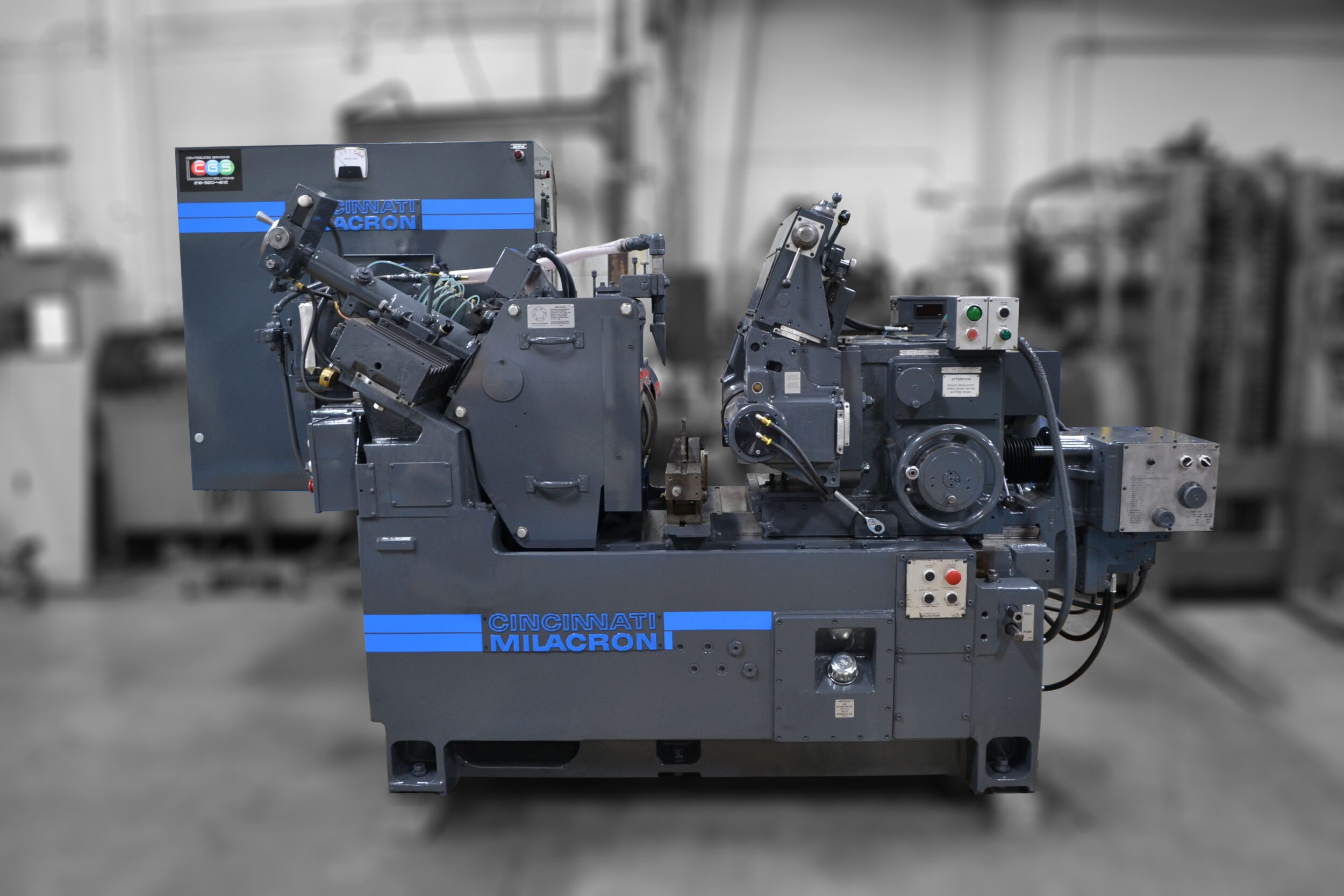

“RK” Series Centerless Grinder

“RK” Series Centerless Grinder

- 24″ Grind Wheel Diameter

- 20″ Wide Grinding Wheel & Regulating Wheel

- 50 HP Grinding Wheel Motor

- “Twin Grip” Grinding Wheel & Regulating Wheel Spindle

- 8,500 SFPM Grinding Wheel Speed

- Precision Linear Rail System

- Advanced CNC Control System

- Granite Epoxy Base for High Strength Static Stiffness

Viking Super Series Centerless Grinder

Viking Super Series Centerless Grinder

- Precision Centerless Grinding Technology

- Capable of Grinding Stainless Steel, Inconel, and Titanium

- 0.001 mm Machine Resolution for High Accuracy

- Ideal for Aerospace, Medical, and Automotive Components

What Our Customers Say

Check Out Our Resource Center!!!

The Complete Guide to the Centerless Grinding Process

For maintenance managers, plant operators, and manufacturing decision-makers, understanding the centerless grinding process is essential. This method delivers precision that other approaches can't match, maintains tight tolerances, and provides...

7 Advantages of Centerless Grinding That Improve Your Production

Precision matters in manufacturing. A part too large or too small means rejected products, wasted materials, and lost time. Traditional grinding methods introduce uncertainty. Centerless grinding eliminates guesswork, delivering consistent...

Preventative Maintenance and Cincinnati Milacron Troubleshooting

Your Cincinnati Milacron grinder runs smoothly until it doesn't. Then everything stops. Unplanned downtime costs major manufacturers $1.4 trillion annually. In automotive manufacturing alone, a single hour of unexpected downtime can drain $2.3...

Let's Work Together

We are dedicated to delivering cost-effective centerless grinding solutions that reduce downtime, boost efficiency, and achieve the finest quality in precision grinding. Ready to discuss your specific requirements or need more details? Contact us today. Our experts are always ready to assist you.