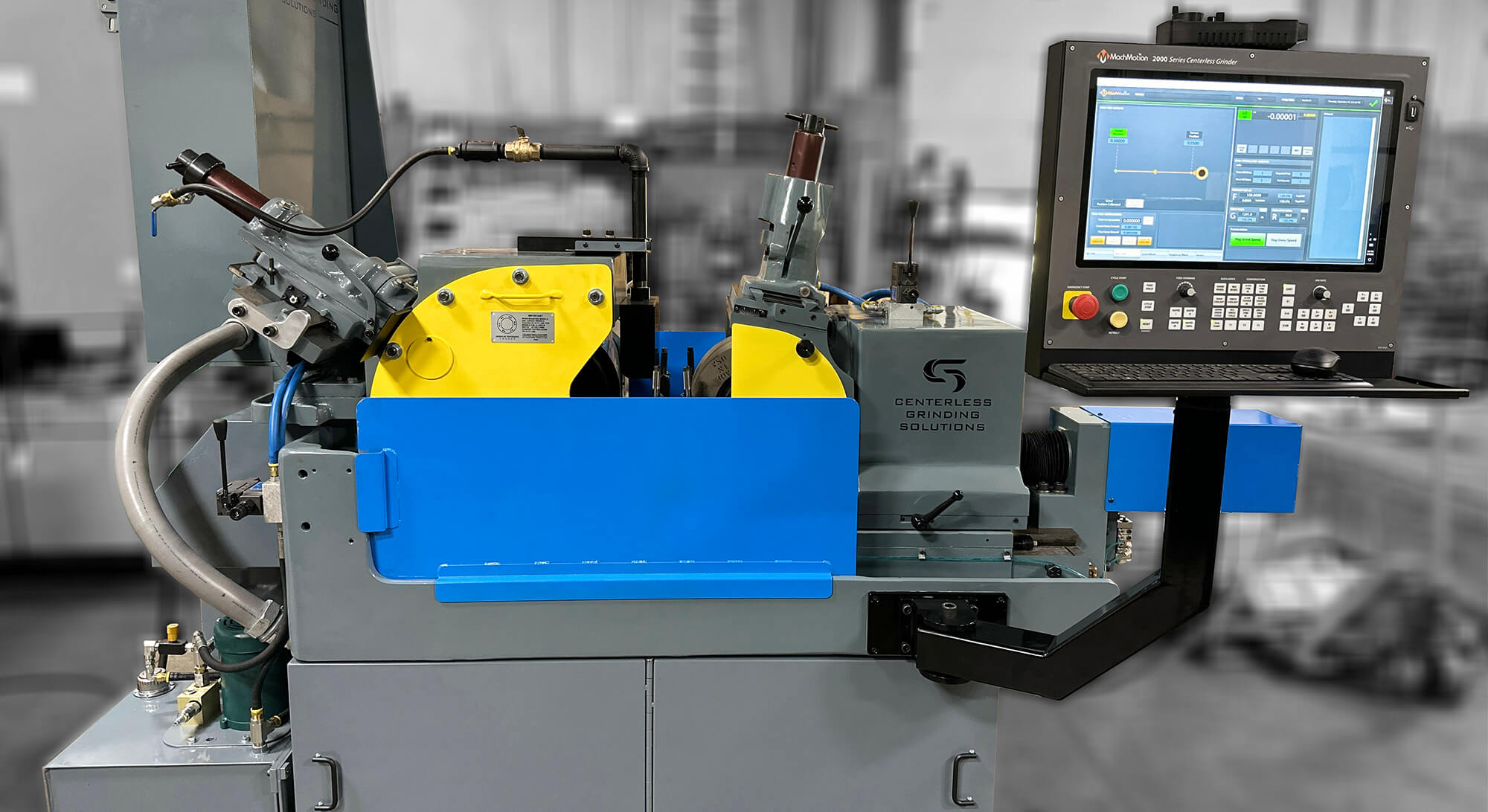

Properly maintaining your centerless grinder ensures your machine keeps up with the increased demand for productivity and helps alleviate catastrophic breakdowns. Our preventative maintenance checklist includes:

Proactive Centerless Grinder Maintenance: Safeguarding Your Productivity

- Inspecting and verifying machine base level accuracy

- A complete hydraulic system checkup including Hydraulic Filters, Oil Level, Oil Temperature, Leak inspection, Hose inspection and replacement of any worn or broken hoses.

- Lubrication system checkup including Verify Lubrication Oil Level, Verify Lubrication Blocks are working properly, Check for worn or broken lubrication lines

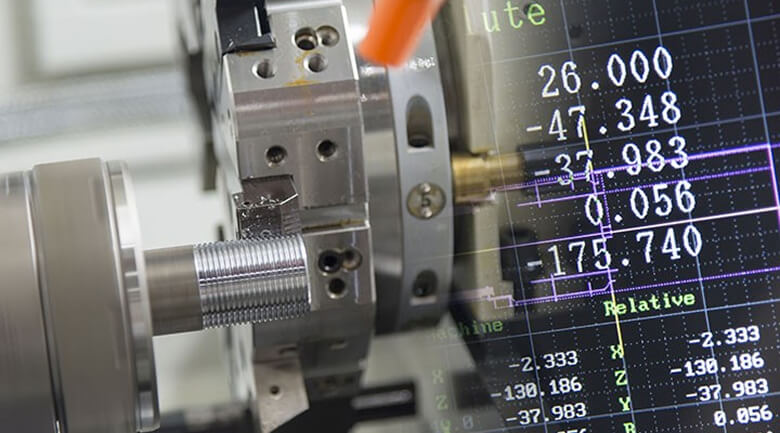

Spindles– Grinding Wheel & Regulating Wheel checkup including Spindle Bearing Clearance Check for Leaks, Spindle Temperature and Spindle Pressures are accurate - Truing/Dressers– Inspect Condition of Ways, Way Covers, Adjust Gibs, Check condition of anti-backlash screw & nut assembly/ ballscrew, Verify Lubrication Blocks are working properly

- Upper Slide, Lower Slide, Swivel Plate– Inspect Condition of Ways, Adjust Gibs, Inspect Ballscrew Cover, Check for excessive wear on Ballscrew Inspect Way Wipers, Verify Lubrication Blocks are working properly

- Regulating wheel drive unit – Inspect overall condition of the unit installed (OEM Drivebox/Aftermarket Servo Drive) Inspect Belt Condition, Verify proper chain tension

- Grinding Wheel Drive Unit– Ensure Grinding Wheel Motor is securely mounted, Inspect overall condition of grinding wheel belts and check for excessive vibration less Grinding Solutions comes with a 24 month limited warranty*

What Our Customers Say

Let's Work Together

We are dedicated to delivering cost-effective centerless grinding solutions that reduce downtime, boost efficiency, and achieve the finest quality in precision grinding. Ready to discuss your specific requirements or need more details? Contact us today. Our experts are always ready to assist you.