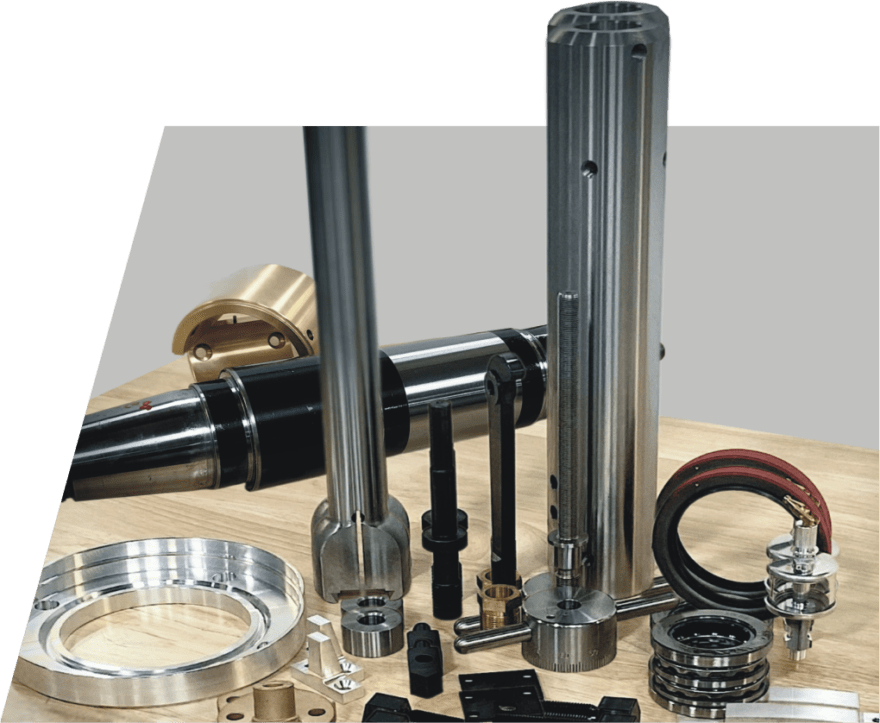

Grinder Parts and Accessories for Specialized Grinding Applications

In the precision-driven world of manufacturing, specialized grinding applications demand perfection. The unsung heroes are the heart of these intricate processes: grinder parts and accessories. These components, often overlooked, play a pivotal role in achieving the exacting standards required for complex grinding tasks.

For manufacturers pushing the boundaries of precision, selecting the right parts and accessories is not just a matter of compatibility—it’s a strategic decision that can make or break production goals. Each component contributes to the final product’s quality, from workrest blades supporting your workpiece to spindle assemblies maintaining unwavering accuracy.

As we delve into specialized grinding, we’ll explore how choosing the right parts and accessories can elevate your grinding operations. Whether working with challenging materials or striving for micron-level tolerances, understanding the impact of quality components is critical to unlocking your grinder’s full potential.

Common Challenges in Specialized Grinding Applications

Manufacturers venturing into specialized grinding applications often encounter unique hurdles that can impact productivity and part quality. Understanding these challenges is the first step towards overcoming them:

- Part Compatibility:

-

-

- Finding parts that fit perfectly with your specific grinder model, especially for older or less common machines

- Ensuring compatibility between new parts and existing components to maintain optimal performance

-

- Material-Specific Demands:

-

-

- Adapting to the varying hardness and composition of specialized materials

- Achieving consistent surface finishes across different material types

-

- Precision Tolerances:

-

-

- Maintaining micron-level accuracy throughout extended grinding operations

- Compensating for thermal expansion and vibration that can affect precision

-

- Wear and Tear:

-

-

- Managing the accelerated wear on grinding wheels and accessories when working with abrasive materials

- Balancing the need for frequent part replacements with production schedules

-

- Process Optimization:

-

-

- Fine-tuning grinding parameters to achieve the perfect balance between speed and quality

- Minimizing setup time and changeovers without compromising precision

-

- Knowledge Gap:

-

- Training operators to understand the nuances of specialized grinding techniques

- Keeping up with advancements in grinding technology and best practices

Addressing these challenges requires high-quality parts and accessories and a deep understanding of the grinding process.

The Role of Specialized Parts in Achieving Grinding Success

Regarding specialized grinding applications, the importance of using the right parts cannot be overstated. These components are the linchpin in achieving consistent, high-quality results. Let’s explore how essential parts contribute to grinding success:

Workrest Blades:

- Act as a critical support system for the workpiece during grinding

- High-quality blades maintain proper alignment, reducing the risk of taper or out-of-roundness

- Specialized coatings can improve wear resistance and reduce friction, extending blade life

Spindle Assemblies:

- form the heart of the grinding machine, directly impacting accuracy and surface finish

- Precision-engineered spindles minimize runout, ensuring consistent material removal

- Robust designs help dampen vibrations, which is crucial for achieving acceptable tolerances

Regulating Wheels:

- Control the speed and feed rate of the workpiece

- Specialized materials and designs can improve grip on challenging materials

- Proper selection ensures consistent throughput without compromising surface quality

Grinding Wheels:

- Directly impact material removal rate and surface finish

- Specialized bonds and abrasives cater to specific materials and applications

- Proper selection balances aggressive cutting with desired surface characteristics

Control Systems and Sensors:

- Modern, specialized controls allow for precise adjustments during the grinding process

- Advanced sensors can detect and compensate for wear, maintaining consistency over time

Coolant Delivery Systems:

- Crucial for heat management and chip removal in demanding applications

- Specialized nozzles and filtration systems optimize coolant delivery and effectiveness

By investing in high-quality, application-specific parts, manufacturers can:

- Enhance overall grinding precision and repeatability

- Extend the lifespan of their grinding equipment

- Reduce downtime for maintenance and adjustments

- Improve part quality and consistency, even for challenging materials

Understanding the role of each component and how they interact is vital to optimizing your grinding process.

Optimizing Performance Through Expert Service and Support

While high-quality parts are essential, maximizing the potential of your specialized grinding applications requires more than just components. Expert service and support are crucial in optimizing performance and ensuring long-term success.

Preventative Maintenance:

- Regular inspections catch potential issues before they become costly problems

- Scheduled maintenance keeps machines running at peak efficiency

- Proper lubrication and alignment checks extend the life of critical components

Precision Calibration:

- Expert technicians ensure your grinder maintains micron-level accuracy

- Regular calibration compensates for wear and environmental factors

- Fine-tuning of control systems optimizes performance for specific applications

Spindle Repair and Rebuilding:

- Specialized knowledge in repairing complex spindle assemblies

- Precision balancing and runout correction restore like-new performance

- Upgrades to modern bearing technologies can improve speed and accuracy

Customized Training:

- Operator training tailored to your specific grinding applications

- Best practices for setup, operation, and maintenance of specialized equipment

- Continuous education on new grinding techniques and technologies

On-Demand Troubleshooting:

- Rapid response to unexpected issues minimizes downtime

- Remote diagnostics capabilities for quick problem identification

- Expert advice on process optimization for challenging materials or tolerances

Machine Refurbishment:

- Breathing new life into older grinding equipment

- Upgrades to modern control systems and components

- Cost-effective alternative to purchasing new machinery

By combining top-quality parts with expert service and support, manufacturers can:

- Maximize uptime and productivity

- Consistently achieve tight tolerances and superior surface finishes

- Extend the lifespan of their grinding equipment

- Stay competitive with the latest grinding technologies and techniques

Partnering with a knowledgeable service provider ensures that your specialized grinding operations meet and exceed expectations, even as demands evolve.

Conclusion

In specialized grinding applications, success hinges on the synergy between high-quality parts, expert knowledge, and ongoing support. By investing in the right components—from precision-engineered workrest blades to advanced spindle assemblies—manufacturers can push the boundaries of what’s possible in grinding operations.

However, parts alone aren’t enough. The complexities of specialized grinding demand a holistic approach that combines top-tier components with expert service and support. This comprehensive strategy optimizes current operations and future-proofs your grinding processes against evolving industry demands.

As you navigate the challenges of specialized grinding, remember that the right partner can make all the difference. You can transform your grinding operations from a potential bottleneck into a competitive advantage with the proper parts, knowledge, and support.

Contact Centerless Grinding Solutions today for a consultation on our comprehensive range of grinder parts, accessories, and expert services. Let us help you unlock the full potential of your grinding equipment and achieve unparalleled precision in your manufacturing processes.