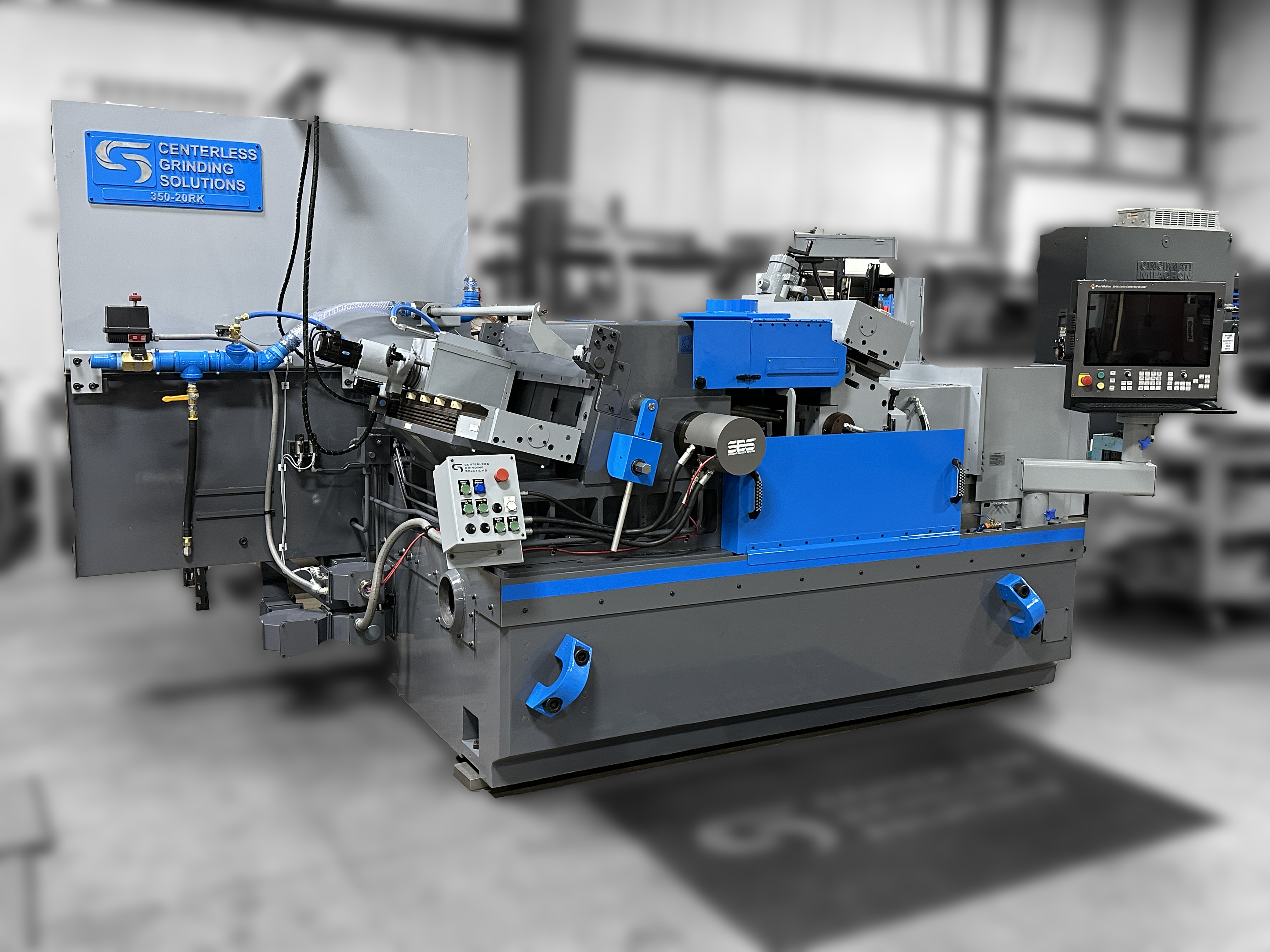

The 350-20 Twin Grip RK Series centerless grinder delivers high-performance precision grinding for both cylindrical and non-cylindrical applications. Centerless Grinding Solutions uses these robust machines to achieve superior accuracy and productivity, with automation and CNC upgrades available for enhanced efficiency.

350-20 Twin Grip RK Series

- 24” Grinding Wheel Diameter

- 50 HP Grinding Wheel Motor

- 8,500 SFPM Grinding Wheel Speed

- “Twin Grip” Supported Grinding & Regulating Wheel Spindles

- 24″ Grind Wheel Diameter

- 50 HP Grinding Wheel Motor

- 8,500 SFPM Grinding Wheel Speed

- Up to 6” Workpiece Diameter Capacity

- Advanced CNC Control System

- Granite Epoxy Base for High Strength Static Stiffness

Available Machine Upgrades

- CNC Grinding Wheel Truing

- Upgraded Grinding Wheel Drive Motor

- SBS Dynamic Wheel Balance System

- Automation

- Robotics & More

| CAPACITIES | S.A.E | METRIC |

|---|---|---|

| Minimum workpiece diameter | 0.500 in | 12.7 mm |

| Maximum workpiece diameter | 6.00 in | 152.4 mm |

| WHEELHEAD | ||

| Grinding Wheel Max Diameter | 24.00 in | 609.6 mm |

| Max Wheel Width | 20.00 in | 508.0 mm |

| Surface Feet Per Minute | 8,500 sfpm | |

| Grinding Wheel Horsepower | 50 HP | 37.3 kw |

| REGULATING WHEEL | ||

| Regulating Wheel Size-Width | 20.00 in | 508.0 mm |

| Regulating Wheel Max Diameter | 14.00 in | 355.6 mm |

| Regulating Wheel RPM | 0 – 300 RPM | |

| Regulating Wheel HP | 5.39 HP | 4.02 kw |

| Machine Weight (approx.) | 25,980 lbs. | 11,785 kg |