The Benefits of Grinder Remanufacturing: A Cost-Effective Solution

Cincinnati Milacron centerless grinders have long been the workhorses of countless production lines. But what happens when these reliable machines show wear-and-tear signs? As production managers and engineers, you’re faced with a critical decision: invest in brand-new equipment or find an alternative solution.

The challenge is real. Aging grinders can lead to decreased accuracy, more frequent breakdowns, and a hit to your bottom line. Replacing these machines with new ones is daunting, especially considering the hefty price tag and potential disruption to your operations.

Enter grinder remanufacturing – a game-changing approach revolutionizing how industries maintain and upgrade their grinding equipment. This process offers a lifeline to businesses looking to enhance their grinding capabilities without breaking the bank.

Remanufacturing your Cincinnati Milacron grinders isn’t just a quick fix; it’s a strategic move that can breathe new life into your equipment. By opting for this route, you can gain extended equipment life, improved performance, and significant cost savings while minimizing your environmental footprint.

The Benefits of Grinder Remanufacturing

Slash Your Upfront Investment

One of the most compelling reasons to consider grinder remanufacturing is its substantial cost savings compared to purchasing new equipment. When you opt for remanufacturing:

- You can typically expect to spend 40-60% less than the cost of a new machine.

- This freed-up capital can be redirected to other critical business areas, such as R&D or expanding your production capacity.

For many businesses, especially small—to medium-sized enterprises, this reduction in upfront costs can mean the difference between upgrading their grinding capabilities or continuing with suboptimal equipment.

Maximize Your Return on Investment

Remanufacturing doesn’t just save you money in the short term; it also helps you squeeze more value out of your initial investment in Cincinnati Milacron grinders. Here’s how:

- Extended lifespan: A properly remanufactured grinder can operate at peak performance for many additional years, often rivaling a new machine’s lifespan.

- Improved efficiency: Upgrades made during the remanufacturing process can enhance your grinder’s performance, potentially increasing overall productivity.

- Reduced maintenance costs: With renewed components and updated systems, unexpected breakdowns and associated maintenance expenses are likely to decrease significantly.

By choosing to remanufacture, you’re not just patching up an old machine – you’re making a wise, long-term investment in your production capabilities.

Restore Original Performance Specifications

When you choose to remanufacture your Cincinnati Milacron centerless grinder, you’re not just fixing what’s broken but restoring the machine to its original glory and often beyond. Here’s what you can expect:

- Precision recalibration: Every critical component is carefully inspected, repaired, or replaced to meet or exceed original factory specifications.

- Enhanced accuracy: With renewed guideways, spindles, and control systems, your remanufactured grinder can achieve the tight tolerances required for modern manufacturing.

- Improved surface finish: Upgraded abrasive technology and optimized machine dynamics can produce superior surface quality on your workpieces.

The result? A machine that performs as well as – if not better than – the day it first hit your shop floor.

Minimize Downtime and Boost Reliability

In the world of manufacturing, time is money. Unplanned downtime can wreak havoc on your production schedules and bottom line. Remanufacturing addresses this head-on:

- Proactive problem-solving: The comprehensive remanufacturing process identifies and addresses potential failure points before they become issues.

- Updated components: Worn parts are replaced with new, often improved versions, reducing the likelihood of unexpected breakdowns.

- Modern control systems: Integrating the latest control technology can improve machine responsiveness and provide better diagnostic capabilities.

By investing in remanufacturing, you’re not just fixing today’s problems but preventing tomorrow’s headaches. This proactive approach translates to:

- Fewer emergency repairs

- More predictable maintenance schedules

- Increased overall equipment effectiveness (OEE)

For many businesses, the improved reliability alone justifies the investment in remanufacturing. After all, what’s the value of a high-performance machine if you can’t count on it when you need it most?

Embrace Sustainable Manufacturing Practices

In an era where environmental consciousness is not just a buzzword but a business imperative, grinder remanufacturing offers a compelling eco-friendly alternative to buying new. Let’s explore how this process contributes to a more sustainable manufacturing ecosystem:

Reduce Your Carbon Footprint

Remanufacturing your Cincinnati Milacron centerless grinder can significantly lower your operation’s environmental impact:

- Energy conservation: The remanufacturing process typically consumes 60-80% less energy compared to producing a new machine.

- Raw material preservation: Reusing the existing machine frame and components reduces the demand for new raw materials and the associated environmental costs of mining and processing.

- Waste reduction: Remanufacturing keeps large, complex machines out of landfills, where they would otherwise contribute to industrial waste.

These factors combine to reduce your carbon footprint substantially, helping your business meet sustainability goals and comply with increasingly stringent environmental regulations.

Align with Circular Economy Principles

Grinder remanufacturing is a prime example of circular economy principles in action:

- Extended product lifecycle: By giving your grinder a second (or third) life, you’re maximizing the value of the resources already invested in its production.

- Closed-loop manufacturing: Many remanufacturers implement processes to recycle or repurpose components that can’t be reused, further reducing waste.

- Sustainable supply chain: Choosing remanufacturing supports a network of businesses focused on repair and restoration rather than constant new production.

By opting for remanufacturing, you’re making a wise business decision and contributing to a more sustainable industrial future.

Enhance Your Green Credentials

In today’s market, environmental responsibility can be a powerful differentiator:

- Meet customer expectations: Many clients, especially in industries like automotive and aerospace, are increasingly prioritizing suppliers with robust sustainability practices.

- Regulatory compliance: Stay ahead of environmental regulations by adopting eco-friendly manufacturing processes.

- Brand reputation: Showcase your commitment to sustainability, potentially opening doors to new business opportunities and partnerships.

Remanufacturing your grinders clearly conveys that your business is committed to responsible, forward-thinking manufacturing practices.

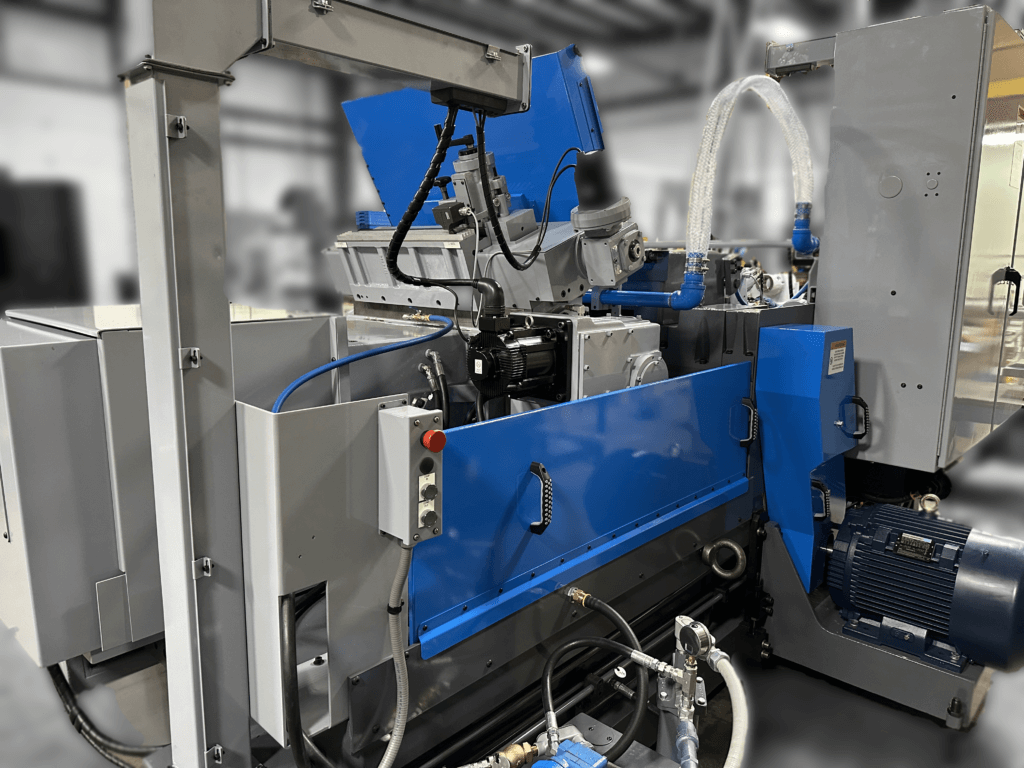

Grinder Remanufacturing: A Comprehensive Process

Understanding the remanufacturing process helps you appreciate the value and quality invested in revitalizing your Cincinnati Milacron centerless grinder. Here’s a step-by-step breakdown of this meticulous process:

- Initial Assessment Experienced technicians disassemble the grinder, documenting each component’s condition. This evaluation forms the foundation for the entire remanufacturing plan.

- Frame Restoration The grinder’s frame, the machine’s backbone, is refurbished to ensure geometric accuracy and provide a solid base for all other components.

- Component Reconditioning Critical parts like spindles, slides, and bearings are either reconditioned or replaced with high-quality components that meet or exceed original specifications.

- Technology Integration Modern technology is incorporated, potentially including control system upgrades, enhanced hydraulics, or advanced sensors for improved performance and monitoring.

- Quality Control Each remanufactured component undergoes rigorous testing to ensure it meets required specifications, maintaining the highest standards throughout the process.

- Precision Reassembly Technicians meticulously rebuild the grinder, ensuring perfect alignment and calibration of all components.

- Comprehensive Testing The fully assembled machine undergoes extensive testing and grinding test pieces to verify accuracy, surface finish quality, and overall performance.

- Final Inspection and Delivery After passing all tests, the grinder is finally inspected before being prepared for delivery to your facility.

This exhaustive process, typically spanning several weeks, results in a Cincinnati Milacron centerless grinder restored to its former glory – often with enhanced capabilities exceeding its original specifications.

Conclusion

Grinder remanufacturing emerges as a game-changing solution for businesses relying on Cincinnati Milacron centerless grinders. This process not only breathes new life into aging equipment but also offers substantial cost savings compared to purchasing new machines. Remanufacturing ensures your grinding operations remain competitive and efficient by restoring original performance specifications, enhancing reliability, and allowing for custom upgrades.

Beyond the immediate benefits, choosing to remanufacture aligns your business with sustainable manufacturing practices. It’s a decision that reflects a commitment to responsible resource management and circular economy principles. Moreover, the ability to integrate modern technology during the remanufacturing process positions your operations at the forefront of grinding technology, ready to meet future challenges and opportunities in precision manufacturing.

Ready to explore how grinder remanufacturing can transform your operations? Take the first step today and request a quote. Discuss your specific needs, ask about their expertise with Cincinnati Milacron equipment, and request case studies of successful projects. By choosing remanufacturing, you’re not just maintaining equipment – you’re investing strategically in your company’s future, enhancing productivity, and gaining a competitive edge in today’s demanding manufacturing landscape.