Viking Spindle Assemblies: A Deep Dive into Quality and Performance

When it comes to centerless grinding, precision is everything. The key to achieving unparalleled accuracy, superior surface finishes, and unmatched efficiency lies in the heart of your grinding machine: the spindle assembly. Among the various options available, Viking Spindle Assemblies stand out as the gold standard, renowned for their exceptional quality and performance. In this in-depth article, we’ll explore the critical role of spindle assemblies in centerless grinding and unveil why Viking Spindle Assemblies are the top choice for industry professionals seeking to elevate their grinding operations to new heights.

The Role of Spindle Assemblies in Centerless Grinding

At the core of every centerless grinding machine lies the spindle assembly, a precision-engineered component that plays a crucial role in determining the quality and efficiency of the grinding process. The spindle assembly is not just a part, but a key determinant of the final grinding results. It is responsible for holding and rotating the grinding wheel at high speeds, ensuring consistent contact with the workpiece. The stability, accuracy, and smoothness of this rotation directly impact the final results, affecting factors such as:

Grinding speed: A well-designed spindle assembly lets the grinding wheel rotate optimally, allowing for faster material removal rates and increased productivity.

Accuracy: The spindle assembly’s precision bearings and rigid construction minimize vibrations and deflections, resulting in tighter tolerances and improved dimensional accuracy of the ground components.

Surface finish: A high-quality spindle assembly ensures smooth, consistent rotation of the grinding wheel, reducing chatter and vibration marks on the workpiece surface, ultimately leading to superior surface finishes.

To achieve these benefits, it is essential to choose a spindle assembly built to withstand the rigors of centerless grinding. High-quality spindle assemblies feature precision bearings, robust seals, and premium lubrication systems that provide long-lasting performance and reliability. Investing in a top-tier spindle assembly enhances the quality of your grinding results and reduces downtime and maintenance costs in the long run.

The Viking Spindle Assembly Advantage

Regarding centerless grinding, not all spindle assemblies are created equal. Viking Spindle Assemblies have earned a reputation for being the premier choice among industry professionals, and for good reason. These meticulously crafted components offer a range of unique features and benefits that set them apart from generic spindle assemblies:

- Precision engineering: Viking Spindle Assemblies are designed and manufactured to the highest standards, utilizing state-of-the-art technology and rigorous quality control processes. This ensures that each spindle assembly delivers uncompromising precision and reliability.

- High-quality materials: Every Viking Spindle Assembly uses premium materials, such as high-grade steel, precision bearings, and advanced sealing systems. These superior components work together to provide exceptional durability, thermal stability, and resistance to wear and tear.

- Customization options: Viking Spindle Assemblies can be tailored to meet the specific requirements of your centerless grinding application. Whether you need a specific size, speed range, or mounting configuration, Viking has the expertise to deliver a spindle assembly that perfectly fits your needs.

By choosing a Viking Spindle Assembly for your centerless grinder, you can expect a range of tangible benefits that directly impact your bottom line:

- Extended machine life: Viking Spindle Assemblies’ superior construction and materials help reduce wear and tear on your grinding machine, ultimately extending its lifespan and minimizing costly downtime.

- Improved grinding precision: Viking Spindle Assemblies’ enhanced stability and accuracy translate into tighter tolerances and more consistent grinding results, allowing you to produce higher-quality parts with greater efficiency.

- Increased productivity: With faster grinding speeds and reduced need for maintenance, Viking Spindle Assemblies enable you to streamline your grinding operations and boost overall productivity.

When compared to generic spindle assemblies, the difference is clear. Viking Spindle Assemblies offer quality, performance, and reliability that inferior alternatives cannot match. Investing in a Viking Spindle Assembly makes you commit to excellence in your centerless grinding operations.

Why Choose Genuine Viking Spindle Assemblies?

When the success of your centerless grinding operations relies on the performance of your spindle assembly, it’s crucial to choose genuine Viking Spindle Assemblies. While opting for cheaper, generic alternatives may be tempting, the risks associated with using incompatible or inferior components far outweigh any short-term cost savings.

Genuine Viking Spindle Assemblies are designed and manufactured to seamlessly integrate with your centerless grinding machine, ensuring optimal performance and compatibility. These spindle assemblies undergo rigorous testing and quality control measures to guarantee that they meet the highest standards of precision and reliability.

In contrast, generic spindle assemblies often lack the necessary precision and durability, leading to problems such as increased vibration, reduced accuracy, and premature wear. These issues compromise the quality of your grinding results and can cause significant damage to your machine, resulting in costly repairs and extended downtime.

Investing in genuine Viking Spindle Assemblies is a smart choice for the long-term success of your centerless grinding operations. By prioritizing quality and compatibility, you can ensure that your grinding machine operates at its peak performance, delivering consistent results and maximizing your return on investment.

Key Takeaways

- Spindle assemblies are critical in centerless grinding, impacting grinding speed, accuracy, and surface finish.

- Viking Spindle Assemblies are the gold standard in the industry, offering unmatched precision, durability, and performance.

- Investing in genuine Viking Spindle Assemblies ensures optimal compatibility and reliability, reducing downtime and maintenance costs.

- Choosing Viking Spindle Assemblies over generic alternatives is a smart long-term decision that will ensure the success of your centerless grinding operations.

Conclusion

The choice of spindle assembly plays a critical role in pursuing centerless grinding excellence. Viking Spindle Assemblies are the top choice for industry professionals seeking unmatched precision, durability, and performance. By investing in genuine Viking Spindle Assemblies, you can unlock the true potential of your centerless grinding machine, achieving superior results and maximizing your productivity.

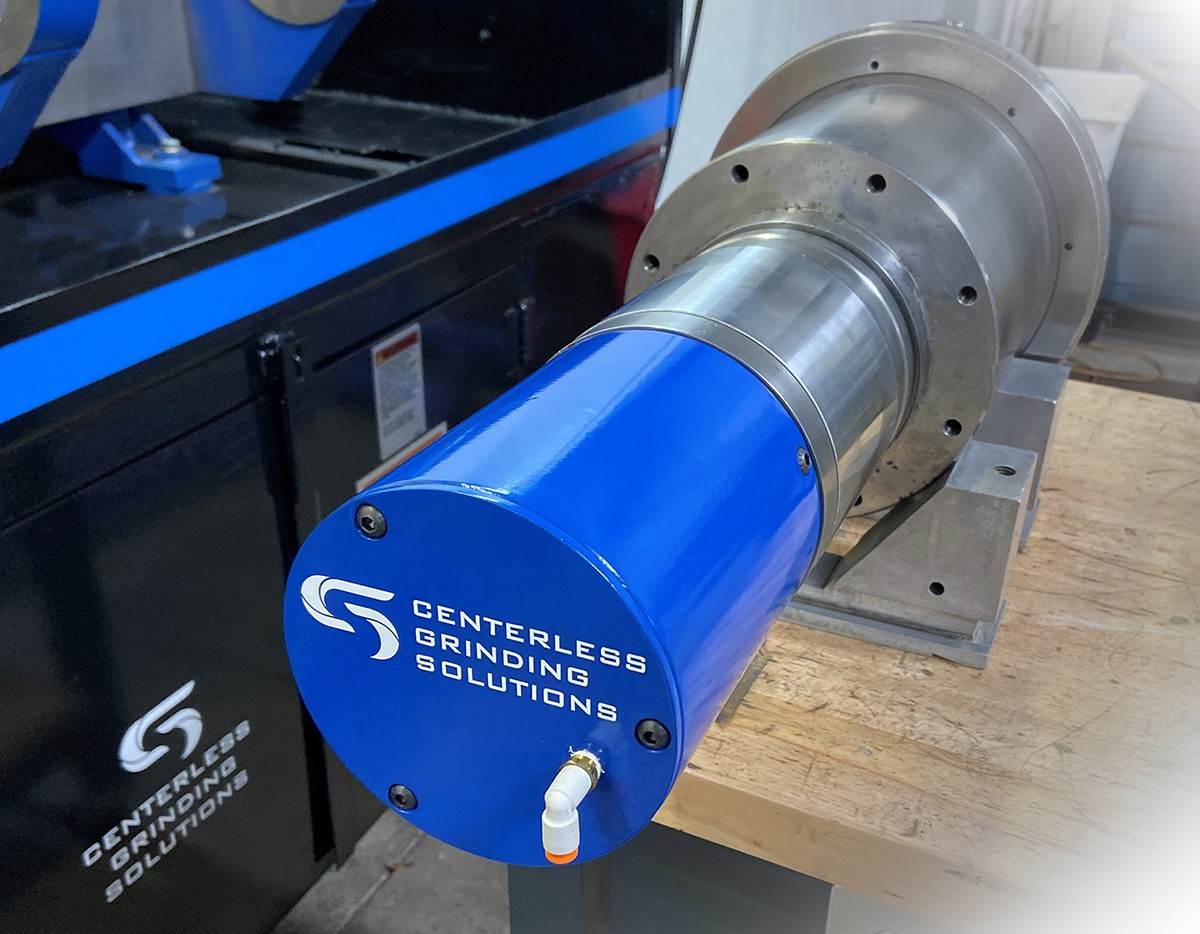

Don’t settle for less than the best. Elevate your centerless grinding operations with Viking Spindle Assemblies and experience the difference that premium quality can make. Contact Centerless Grinding Solutions today to learn more about our Viking Spindle Assembly services and take the first step towards grinding success.